One of the best thing about the fiber optics is- ease of installation. Unlike the other cables which are heavy and complex to establish connection, fiber optic cables are light and flexible to install. The process of installing fiber cable is similar to any wire cable installation, but the method, tools and instruments require to complete the task is different.

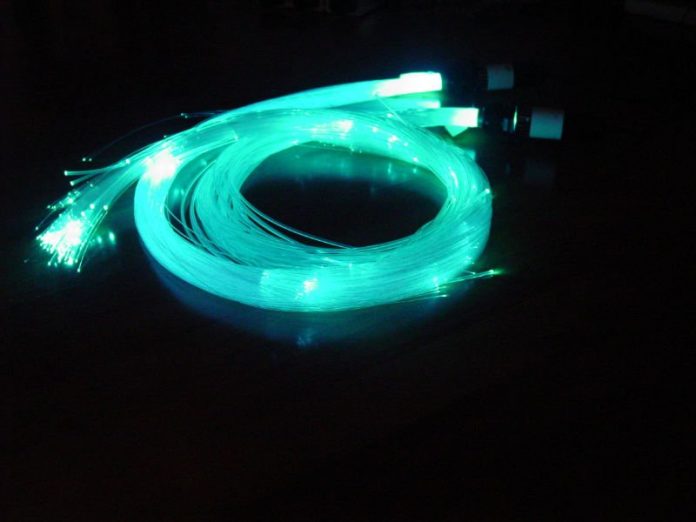

Fiber optics cable may be installed for outdoor underground application or for indoor underwater application using several different installation methods available. Since there are varieties of fiber optics cable and number of applications of it so there is not any thumb rule for installation. However some general guidelines that must be following prior to any type of cable installation are:

Surveying the site

This is the foremost step that must be conducted to recognize the location and its special need. It helps to determine the physical and environmental hazards, and also helpful in cable route and machinery placement planning, especially for fiber optic lightening installation in pools and spa.

Cable stretching plan

The requirement of cable pulling equipments, location of junctions and access points, and splice setting must be planned prior to the installation. For lightning, a complete system along with fiber type i.e. end glow or side glow should be planned carefully.

Don’t twist and exceed bend radius of cable

Twisting the fiber can limit its efficiency by stress on fibers and it should not be practiced during lightning application. Fiber optics cable can be broken if bend radius is exceeded. Bend radius must be twenty times smaller than cable diameter and final installation bend must be ten times smaller than its diameter.

Special attention for fiber optics pool lightning

Fiber optics is waterproof and can be arranged in different patterns for pools and other underwater application. However, safety must be considered before installation. Be cautious about electric current and always dry the pool for installing fiber optics lightning.

Test the light box before installation and place them carefully inside the light fixture. Use of proper tools, accessories and splicing method will help you to achieve desired and hassle free installation.

Testing the complete system:

Different type of testing must be performed in order to achieve desired installation. Test the continuity of the cable with the help of flashlight test. Microscope and magnifiying lenses are used to detect scratches and defects in optical fiber.

Optical time domain reflectometer (OTDR) must be use to determine the length and attenuation of the fiber optics cable. It is used to identify points where losses are occurring and also the broken points.

Following the above guidelines will ensure the proper framing of your site with fiber optics. While laying out fiber optics cable there always a requirement to terminate or elongate the cable, for such cases technique used in fiber optics is completely different than other conventional cable. This method is known as splicing which is practiced to achieve lower insertion loss and it is of two types:

Fusion splicing– In this type a special equipment known as fusion splicer is used to join the fiber cable. In this technique cables are aligned and weld together by generating an electric arc. This results in lower insertion loss.

Mechanical splicing– This type of splicing doesn’t require any special instruments. It simply makes use of mechanical splice that permanently connect optical fiber. Adhesive or snap type cover is use to fasten it completely. It is a quick, easy and handy technique to follow.

Perfect installation can’t be achieved without adequate tools and accessories. During fiber optics installation there are some special and modern equipment that perform this role easily. The fiber optic installer must have the complete set of fiber optics tools and test equipments. Typically the fiber optics tool contains:

- Handling tools such as cable cutter, buffer tube cutter, cable slitter, rip cords, pulling eyes and electrical tape.

- Splicing tools like cable jacket stripper, fiber cleaver, tweezers, polishing puck, plate and pad, fusion splicer and connector crimper.

- Testing equipment such as fiber optic power meter, test source, connector adapter, visual tracer, continuity checker and OTDR.

- Accessories such as O-ring, lens and bulbs for fiber optic lightening system repair and installation.

Problem arises during fiber optics installation and its solution:

- Fiber optic lightening installation requires good ventilation for illuminators. But since fiber optics is ultra violet protected you can install them easily in ventilated area.

- Dark surface absorb the light emitted from the fibers. Try to install them over light surface which make it more reflective for end light or side light fiber.

- Once the lightening cable is cut, you can’t add extra piece on it efficiently. So, estimate the fiber length as accurate as possible or leave extra feet cables for future need.

- Bending of cable should be performed precisely otherwise it leaves bright spot or breaks the cable. Always follows the manual instruction and bend it on recommended radius.

Pros and cons of fiber optics installation:

Fiber optics installation is easy if performed by the experts. However there are always some positive and negative sides of each type of cable installation. Talking about fiber optics pros and cons:

Pros:

- Cable network is so simple that your object won’t look dull during off condition.

- Fiber optics cables are light and thin which makes installation easier.

- These are safer to use and has no risk of electric shock.

- Desired lightening pattern can be achieved for longer time as the cables are flexible and reliable.

Cons:

- Fiber optics cables are of low cost but its installation is quite expensive as it requires special tools, equipment and skilled labor to set up fiber network.

- It requires sensitive installation; attention must be paid while pulling and twisting the cable.

- They may be tricky to install hence required team of experts for proper finish.

Tips for fiber optics installation:

- Measure the fiber cable three times to cut it once- this reduces problem and stress if you come up with short of length.

- Plan your pattern and run of the cable prior by communicating properly. Because after cutting the raw material it’s become difficult to make changes.

- For water application, drained out and dry the pool completely to prevent shock.

- Review the lightning kit installation instruction carefully to place all devices correctly.

Fiber optics lightening installation is far better than any type of cable lightening. It is the best options for your pool to get enchanting glow. Various brands such as Mica, Pentair and Hydro-Quip are renowned names for pool lightening manufacturer. Fiber optics installation are easy to repair, safer to practice, provide inspiring ambience for object and convenient to the user.